- Improved material stability for Heat Assisted Magnetic Recording

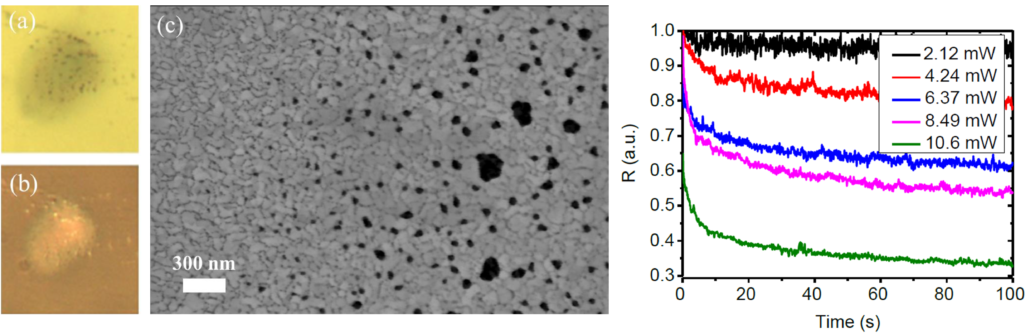

At elevated temperatures microelectronic devices fail due to solid state dewetting and electromigration. We look at techniques to mitigate these effects and improve the operating temperature range and lifetime of electronic and photonic devices. A key finding of this work was that extremely thin (<0.5nm) adhesion layers can be used to significantly improve adhesion of thin metal layers to glass and SiO2 substrates. By monitoring time domain reflection we can understand timescales involved in dewetting and extract diffusion constants.This project is part of a long-standing collaboration with the group of Prof. John Donegan, Western Digital and ASTC.

- Integrated two phase cooling, and heat transfer at solid liquid interfaces.

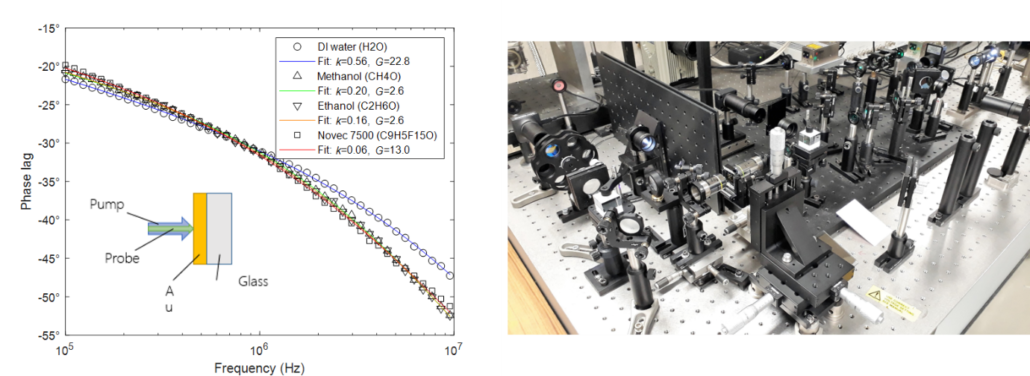

This project is part of a collaboration with the thermal transfer group at Nokia Bell Labs and is primarily funded under an IRC Employment based postgraduate scheme. Continued miniaturisation of electronic components is hampered by increased heat source density. This requires more advanced thermal management techniques. One suggestion is to include two phase evaporative cooling at a device level. There are multiple challenges to implement this solution. We are exploring heat transfer rates at solid liquid interfaces, and liquid gas interfaces which are likely to limit this process. FDTR is an ideal tool to study these processes in a non-contact way in an extreme heat flux regime.

Related Publications: Link

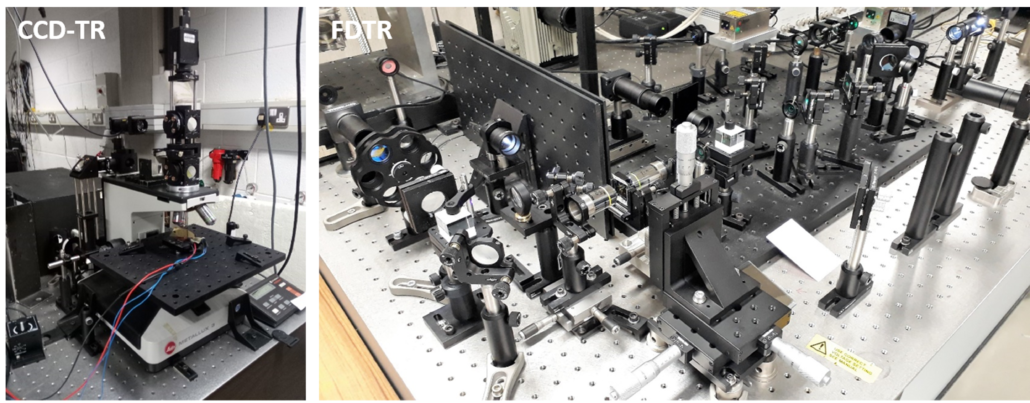

- Characterisation of Thin Film Thermoelectrics

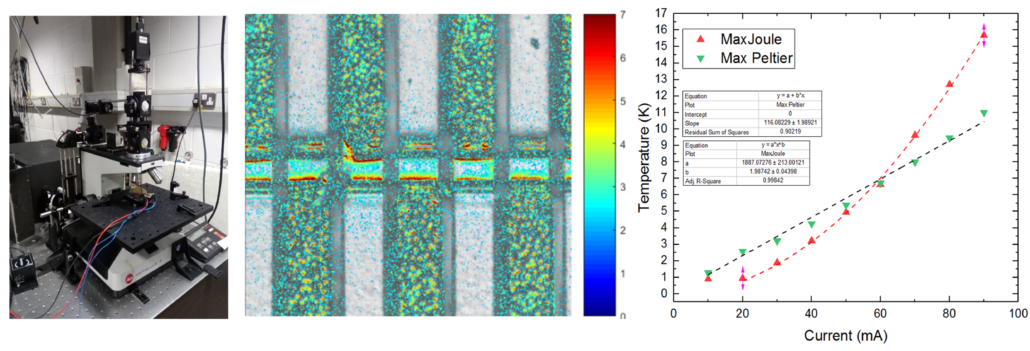

Thermoelectric materials act as solid state electrically controlled heat pumps and can extract heat from a specific component on chip as long is this heat can be removed elsewhere. Thin film thermoelectrics (<10um) have been proposed as an on-chip thermal management solutions. In order to characterise the performance of these devices we must accurately measure Seebeck coefficient, electrical conductivity, and thermal conductivity. All three parameters are difficult to measure simultaneously in a thin film device. We have developed a method using CCD based thermoreflectance which allows for quantitative imaging of the thermal performance of thin film thermoelectrics and devices. Combined with electrical and FDTR measurements we can identify mechanisms limiting the performance of these devices. This project is funded through a Trinity Award, and is in collaboration with Nokia Bell Labs, and the Group of Prof. Kafil Razeeb in Tyndall National Institute.

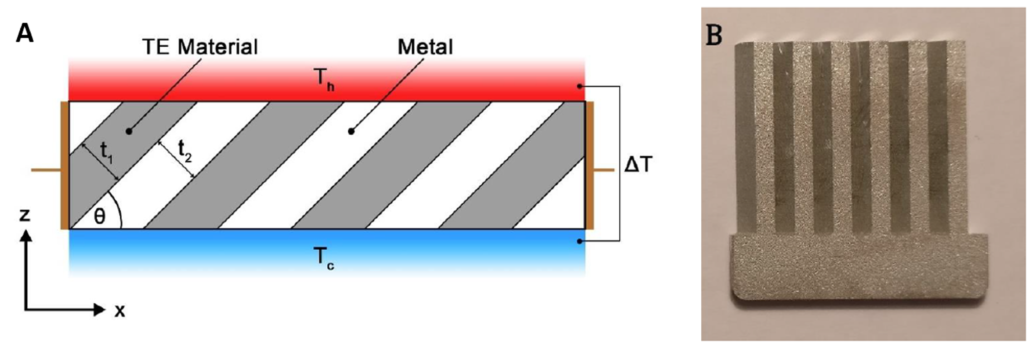

- Transverse Thermoelectrics for Energy harvesting

This project aims to create artificial materials with unique electrical and thermal properties by combing alternating layers of metal and semiconductor. In conventional thermoelectric materials the electric current and heat flux and in the same direction. In these so called transverse thermoelectric materials a heat flux across the device will generate a current in-plane along the device. This opens up the design space significantly both for thermoelectric power generation and thermoelectric cooling. We are exploring different material combinations and fabrication techniques to realize this concept. Our goal is to utilise transverse thermoelectrics for energy harvesting under extreme heat flux conditions. This project is funded by SFI the AMBER research centre.

- Development of Thermal imaging techniques.

We are actively developing methods to improve the sensitivity and accuracy of or thermal imaging techniques. We focus on thermoreflectance techniques which map changes in temperature by picking up small changes in material reflectivity. These are non-contact techniques which are ideally suited for studying microscale devices difficult to study using conventional techniques. Using lasers to generate locaised heat sources alows us to study material performance under extreme heat flux conditions. Thermoreflectance techniques are still under constant development and improvements. We have added to this field by improving accuracy of the theory for CCD-TR and improving the range of thermal conductivity that can be measured using FDTR from 0.1-2000W/m/K.

Completed Projects

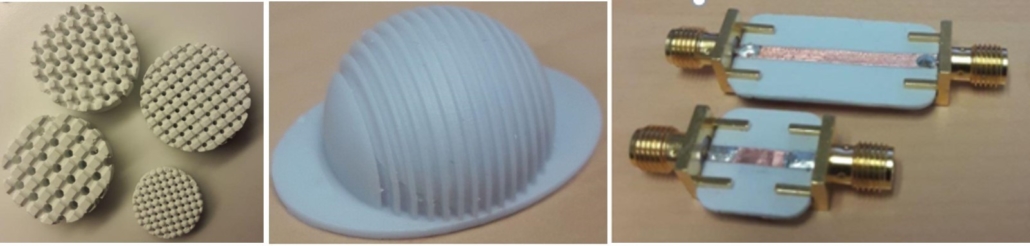

- 3D ceramic printing for RF components.

High permitivity and low loss ceramic components are important for high frequency RF devices such as those proposed for some 5G networks. Components such as filters, lenses and antennae can be fabricated using these low loss dielectrics. Conventionally ceramic materials are limited to simple geometries due to processing constraints. In this work we explored ceramic additive manufacturing for low loss RF components. In particular we demonstrated permitivity control through structure. We developed a range of novel filters, lenses and Luneburg lens designs. This project was funded through the CONNECT research centre, and was in collaboration with the RF device group at Nokia Bell Labs Ireland.

- Thermal imaging of nanowires for electrical interconnects.

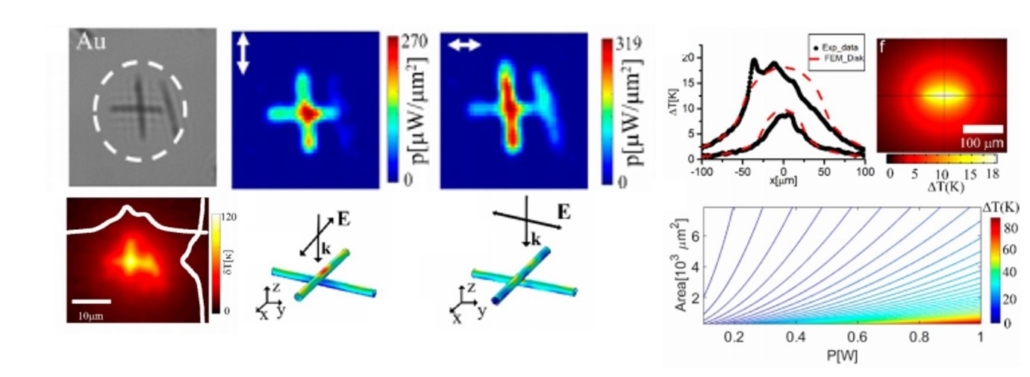

In this work we explored mechanisms of thermal welding in crossed metal nanowires. When illuminated by laser light these nanowires form contacts due to plasmonic heating. Using Phase Shearing interferometry we were able to image the local temperature rise under uniform illumination and reconstruct the heat source density. We showed that this followed the expected electric field enhancement and dependent on the orientation of the nanowires with respect to the laser polarisation. This project was funded under an IRC postdoctoral research fellowship, and the work carried out in collaboration with the group of Prof. Guillaume Baffou in Institute Fresnel Marseille. An IRC Ulysses travel grant was very useful in setting up the collaboration with Prof. Baffou’s group.